Synthetic lubricant for reciprocating air compressors BP Enersyn RX 100

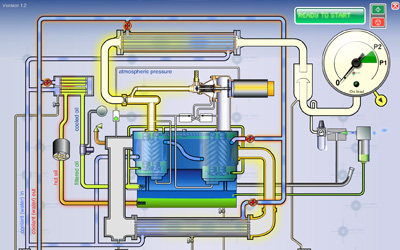

BP Enersyn RX 100 ( Equivalent to Shell Corena S4 p100) is a high performance fully synthetic lubricant (ISO-VG 100) for use in reciprocating air compressors.

Application

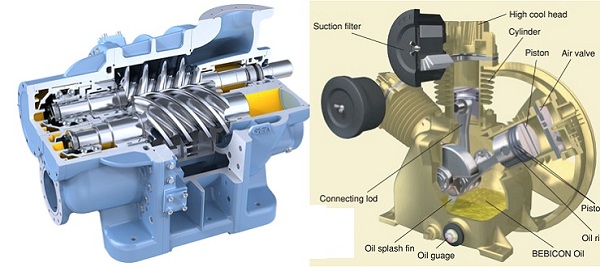

Enersyn RX 100 is recommended for the crankcase and cylinder lubrication of reciprocating air compressors, including those operating at high pressure and elevated temperatures.

Main Performance Features

Low deposit forming tendencies on compressor valves and inter/after stage air coolers

Extended maintenance periods

Increased safety factor due to higher auto-ignition temperature

Low volatility and good oxidation performance resulting in low lubricant consumption and extended service life

Enersyn RX 100 is approved by, or meets the specification requirements of, major air compressor manufacturers for reciprocating air compressors.

Care and Handling

At the initial change to the use of Enersyn RX 100 the compressor lubrication system should be completely drained and cleaned before filling with Enersyn RX 100. The solvency properties of Enersyn RX 100 tend to remove carbon deposits which may be present on compressor valves, inter/after stage air coolers and passages. To ensure safe and trouble-free compressor operation using Enersyn RX 100 an inspection should be undertaken prior to its initial use and any accumulated deposits removed as necessary. Oil and air filters should be inspected and cleaned prior to the use of Enersyn RX 100 and subsequently, periodic inspections should be conducted on a routine basis. Due attention should be given to ensure that the compressor crankcase paint and seal materials incorporated in the entire system are suitable for use with the synthetic base-stocks from which Enersyn RX 100 is blended.

Packaging and Storage

Delivered in small packs of approximately 20 litres. Note the actual size may vary according to country of delivery.

The product should be stored in a protected location and the ingress of contaminants and water avoided. Ensure containers are tightly secured after use.

Được cung cấp bởi:

- CÔNG TY TNHH THƯƠNG MẠI VÀ DỊCH VỤ KỸ THUẬT HẠNH SAN

- Địa chỉ: Số 22, Ngách 85/11, Đường Định Công Thượng, P. Định Công, Q. Hoàng Mai, TP. Hà Nội

- VPGD: P.102, Số 37B, Ngõ 20, Đường Hồ Tùng Mậu, P. Mai Dịch, Q. Cầu Giấy, TP. Hà Nội

- Điện thoại: 094.183.8228 097.796.6472

- Email: bxtlub@gmail.com

- Website: http://hanhsan.com

Copyright © 2016 Công ty TNHH TM&DV Kỹ thuật Hạnh San | design by: dangkha - 0974 624 069